3pcs 100w solar panel High efficiency photovoltaic home flexible cell system kit 300w | Электроника

Сохраните в закладки:

История цены

*История изменения цены! Указанная стоимость возможно, уже изменилось. Проверить текущую цену - >

| Месяц | Минимальная цена | Макс. стоимость | Цена |

|---|---|---|---|

| Sep-18-2025 | 0.84 руб. | 0.55 руб. | 0 руб. |

| Aug-18-2025 | 0.26 руб. | 0.48 руб. | 0 руб. |

| Jul-18-2025 | 0.59 руб. | 0.53 руб. | 0 руб. |

| Jun-18-2025 | 0.42 руб. | 0.98 руб. | 0 руб. |

| May-18-2025 | 0.18 руб. | 0.20 руб. | 0 руб. |

| Apr-18-2025 | 0.26 руб. | 0.93 руб. | 0 руб. |

| Mar-18-2025 | 0.48 руб. | 0.83 руб. | 0 руб. |

| Feb-18-2025 | 0.72 руб. | 0.25 руб. | 0 руб. |

| Jan-18-2025 | 0.37 руб. | 0.66 руб. | 0 руб. |

Новые товары

Портативное складное солнечное зарядное устройство 28 Вт с 3 USB-портами - купить по

Выходное USB зарядное устройство для солнечной батареи гнездовой порт 5 В Вт -

Складная солнечная панель 18 В/5 В 300 Вт USB-аккумулятор полный комплект зарядного

Солнечный комплект 150 Вт 300 450 солнечная панель 12 В Контроллер заряда В/24 30A PV

Портативная перезаряжаемая солнечная панель 6 в генератор энергии зарядное

20/50 шт. 5BB 156*104 мм 2 55 Вт Панель es solares поликристаллический кремний güneş панель i

Переносное солнечное зарядное устройство ALLPOWERS с USB Type-C 5V 21W и аккумулятором на 10000 мАч для путешествий и разворачивания на кемпинге для iPhone, iPad, Xiaomi и других устройств.

Солнечная панель PET 7 Вт 7 В 10 штук черного цвета для создания рюкзака usb-зарядного устройства 5 В или зарядки портативных переводчиков напрямую.

Характеристики

3pcs 100w solar panel High efficiency photovoltaic home flexible cell system kit 300w | Электроника

Описание товара

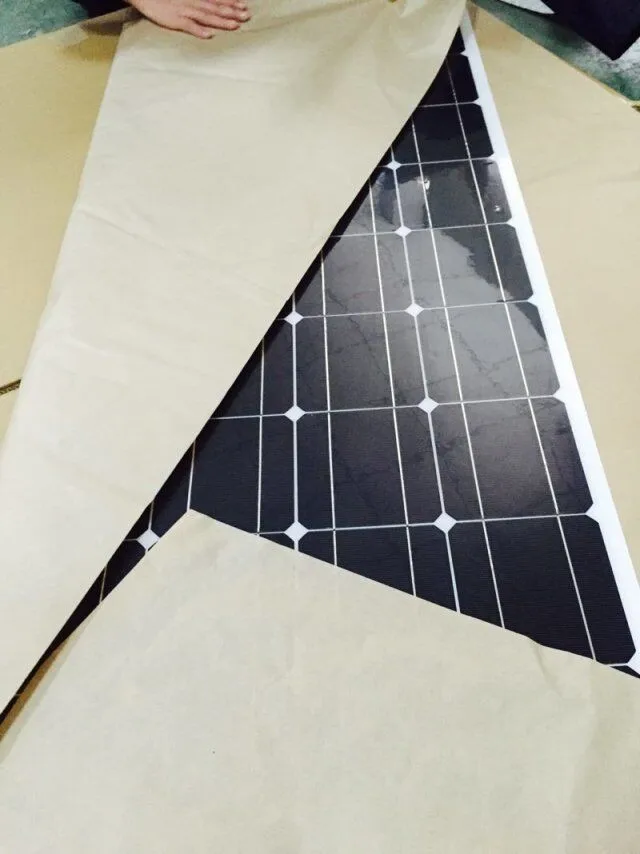

The Plastic Cover on Solar cell is not for use, it is

protect the solar cell while transportation, so when you

use the solar panel, pls remove it!!!

Technician Specification

Length

1050mm

Weight

1.7 kg

Width

540 mm

Main material*

Mono crystalline

Height

2.5 mm

Frame material

EVA+PET OR ETFE+EVA+TPT

Electrical Specification

Performance Under Standard Test Conditions(STC*)

Maximum power

Pmax

100 Wp

Open circuit voltage

Voc

20 V

Maximum power point voltage

Vmpp

18.02 V

Short-circuit current

I sc

5.95 A

Maximum power point current

I mpp

5.55 A

Minor reduction in efficiency under partial load conditions at 25degC: at 100 W/m2, 95%- (+/-3%) of the STC efficiency (1000 W/m2) is achieved.

Component Material

Cells per module

32

Cell dimensions

125mm*125mm

Cell type

Monocrystalline Silicon

Front

ETFE+EVA +TPT or EVA+TPT

System Intergration Technician

Maximum system voltage SC II

1000 V

Maximum reverse current

10 A

Maximum system voltage USA NEC

600 V

Increased snowload acc. to IEC 61215

5.4 kN/msup2;

Thermak Characteristics

NOCT

47 degC

TC Voc

-0.33 %/degC

TC Isc

0.042 %/degC

TC Pmpp

-0.45 %/degC

Extra Specification

PTC rating

100 W

Module efficiency

21.0%

Junction box

IP67

Plus-Sorting*

Pflash ge Pmax

Connector

MC4

Power tolerance*

+/- 3 %

PET Flexible Solar Panel 100w

Products Detail

Products Detail

1.Mono solar cell

1.Mono solar cell

1) Efficient PV conversion, stable performance

2)Unique etching process can increase the short-circuit current of the solar cell

3)Advanced PECVD technology provides well-proportioned navy blue silicon nitride anti-reflection velum

4)Screen printing patterns are accurate and smoothness of the electrode is improved thus making the cell easier for welding and laser cutting

1)Increase conversion efficiency by 5%

2)Enhanced surface abrasion resistance

3)High anti-fouling

4) Easy to clean

3.Backsheet TPT

3.Backsheet TPT

The back sheet of the module is a key package material applied to the module and is mainly composed of a weather-resistant fluorine material and a PET with excellent electrical insulation properties. The service life of such products is generally designed over 25 years, and the back film is the key to ensure such a long life. The solar module back film is located on the outer layer of the module, and the solar panel back film should have high electrical insulation, high weather resistance, high adhesiveness, and low water vapor transmission rate.

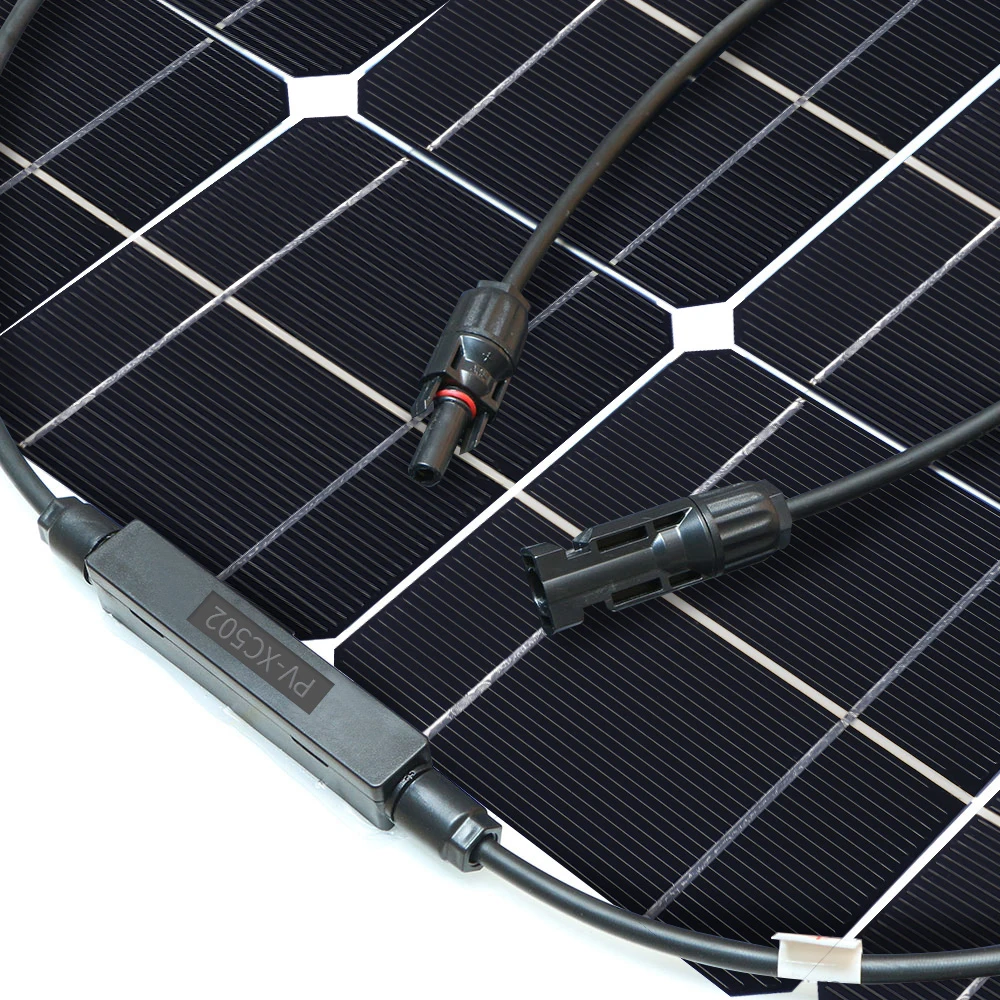

4.Junction box

1)With excellent resistance to high and low temperature, fire, aging and UV resistance, it can meet the long-term use requirements under harsh outdoor environmental conditions.

2) Excellent waterproof and dustproof effect, sealed by pouring glue.

3)Compact size, compact and practical structure, suitable for thin film photovoltaic modules, widely used.

4)The connection of the bus bar and the cable are respectively welded and crimped, and the electrical performance is safe and reliable.

5.MC4 Connector

5.MC4 Connector

1)Highly robustness, UV-Resistance

2)Connector adopts touch and insertion of reed with inner-knob type

3)Auto-lock equipment of male and female points enable connection more easy and reliable

4)Popular figure suits most of field installation

5)Accommodates PV cable with deferent insulation diameters

6)The maximal working current will be changed when fixed with different types of diode

At HETECH Solar, we scour the globe in search of the most suprior materials the industry has to offer. Combined with our near fully automated manufacturing system, we offer consistently high power modules that will last a lifetime. Each material has been carefully tested to meet our best in class standards.

1.Solar cell test

1.Solar cell test

New technology and most superior materials offered. combined with our automated and semi-automated manufacturing and testing system, make sure Solar cell modules high efficiency.

2.WeldingString creation by interconnecting the single photovoltaic cells, then interconnection of the strings in order to create an electrical circuit.

3.Lamination layer

3.Lamination layer

Automatic pick up, rotation and positioning of the strings welding to the glass with high quality encapsulant material.

4.EL TestEL test is able to highlight information that normally is not detectable with visual inspection, power measurement or IR testing, it is possible to identify micro cracks, degradation and shunted area on cells.

5.Lamination

5.Lamination

During this process, the encapsulant material cures and the muti-layer sandwich becomes one unit.

6.Trimming and FramingRemovals of surplus material along the sides, then install the aluminum frame around the module.

7.Power test & IV.

7.Power test & IV.

I-V curve acquisition in STC condition for the measurement of the peak power. It is to make sure all our finished solar panels could be used with high efficiency before delivery.

8. Package & DeliveryEnvironment-friendly and strong packing materials are used to protect the products from damage and ensure that the customers receive the goods in good condition without any damage , and the reasonable and professional packaging method is convenient

to load and upload during transporting and save transportation costs.

About UsJingyang Solar Energy is an international high-tech and growing group company, established in 2009, with 10 years’ experience of solar modules manufacturing and PV power generation systems supplying. Our factory covers an area of 10,000 square meters, employing 150 peoples, with an annual production of 500MW, about USD50 million of annual production value.

Jingyang Solar Energy is mainly engaged in crystalline silicon solar cells, modules, photovoltaic systems engineering and the research, manufacturing and sales of PV application products. In the past decades, Jingyang Energy built a wide sales network in global market which covers more than 68 countries, our major target markets are Europe, USA, Southeast Asia, America, Australia, Africa, etc, Our overseas projects involves State grid solar power plant, household solar system, outside portable solar system,etc

Project Case

Project Case

Packing & Delivery

Packing & Delivery

Packing

Packing

Normally packing: 1pc/2pcs/3pcs/10pcs/25pcs per carton

Individual packing requirement is acceptable.

Трекер стоимости

Отзывы покупателей

Новые отзывы о товарах

Продавец MOM PREFERRED STORE (Электронная продукция) - это не добросовестный продавец. Заказывал здесь планшет, мне прислали другой планшет, намного хуже.... Читать отзыв полностью...

Отзыв о магазине professional-laptop-parts-supplier- fqparts- Store (Рейтинг 73.68%) https://aliexpress.ru/item/40009079 69596.html Заказал клавиатуру для ноутбука Clevo P775TM1-G, которая по заявлению... Читать отзыв полностью...

Самый не порядочный продавец товаров. Не рекомендую! Преобрела хард диск. Оказался бракованный подделкой. Чтобы вернуть деньги за не качественный товар... Читать отзыв полностью...

Выбрала белый вариант. Сидит на мне как на модели, нигде не морщит. Сетчатый верх платья мне особенно нравится, чувствую себя... Читать отзыв полностью...

Покупал квадрокоптер RC drone на маркетплейсе wildberries у данного продавца, пришел товар не работающий и со сломанным пультом управления ,... Читать отзыв полностью...

Планшет бмах11про просто пушка за эти деньги...... Читать отзыв полностью...